High frequency induction heater introduction

HF induction heating equipment 4-80KW with oscillating frequency mainly from 30 to 100KHz, these machines are our earliest models and have been used most widely now because of their simplicity and low price. the machines of this frequency are suitable for brazing, forging and heat treatment and a lot of other applications. For example: brazing of diamond blades, brazing of machining tools, heating of rod for forging, copper tube brazing , shaft quenching and stainless steel vessel annealing and so on. Power range of HF series induction heating equipment from 4-80KW, machines are the simplest, cheapest and most reliable types in our induction heating machines, they have been widely used in all areas of metal heating both in china and abroad.

Model explanation:

HF-XX AB:

HF—high frequency series induction heating machine

XX-- rated input power or oscillating power

AB—additional function A: with timer function B: split type that is with separated transformer

Main models and specifications

| Model | Maximum input power | Oscillating frequency | Max input current | Input voltage | Duty cycle |

|---|---|---|---|---|---|

| HF-04A | 4KW | 100-250KHz | 15A | Single phase 220V 50/60Hz | 80% |

| HF-15A,HF-15AB | 7KW | 30-100KHz | 32A | Single phase 220V 50Hz/60Hz | 80% |

| HF-25A,HF-25AB | 15KW | 30-80KHz | 23A | 3phase 380V 50Hz/60Hz | 80% |

| HF-40AB | 25KW | 30-80KHz | 38A | 3phase 380V 50Hz/60Hz | 100% |

| HF-35AB | 35KW | 30-80KHz | 55A | 3phase 380V 50Hz/60Hz | 100% |

| HF-45AB | 45KW | 30-80KHz | 68A | 3phase 380V 50Hz/60Hz | 100% |

| HF-60AB | 60KW | 30-80KHz | 80A | 3phase 380V 50Hz/60Hz | 100% |

| HF-70AB | 70KW | 30-80KHz | 105A | 3phase 380V 50Hz/60Hz | 100% |

| HF-80AB | 80KW | 30-80KHz | 130A | 3phase 380V 50Hz/60Hz | 100% |

Structure and technology

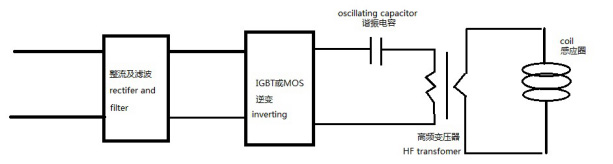

HF-04---80AB induction heating equipments, series oscillating circuit is used, after oscillating circuit, power is output through high frequency transformer, and then there is low voltage and large current going through the induction coil.

In UF-04A, HF-15A/AB, HF-25A/AB induction heating equipments, using MOSFET and IGBT components, our first generation current inverting control technology is adopted, these machines are characterized by simple structure, high reliability and low price, and they are easy to use and repair, So these induction machines are used most widely now both in china and abroad.

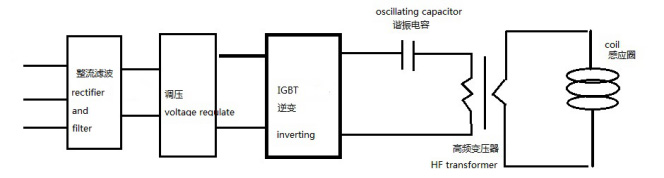

HF-40AB,HF-35AB,HF-45AB have the same structure and same technology, IGBT module and our second generation inverting control technology has been used, that is the dual control and inverting technology. Output power and oscillating frequency are controlled independently. We use IGBT components and high frequency voltage regulate control circuit to control the power and we use IGBT components, series oscillating and automatic tracking circuit to reach soft switching in the inverting course, all these make the machine to be more reliable and make the machine possible to work continuously with 100% duty cycle.

on the basis of soft switch technology, voltage regulate circuit is used to control both the voltage and the current of the IGBT inverting module. By this new technology, the reliability of IGBT is raised greatly and let these induction machines working even more reliably than the first generation machines at large power output level.

Due to the adopting of advanced technology, HF-40AB,HF-35AB,HF-45AB machines are characterized by larger frequency range, smaller size, water cooled transformer, higher reliability and lower repair cost.

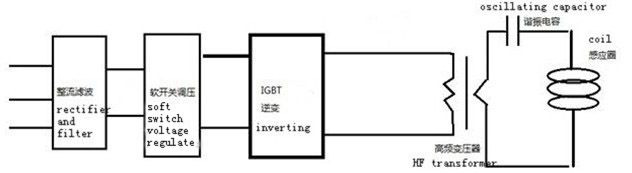

Inside HF-70AB induction heating machine, IGBT module and our third generation inverting control technology has been used, that is the soft and dual control and inverting technology. In this technology, output power and frequency can be controlled and adjusted separately, IGBT module and soft switching control technology are used in the high frequency switching circuit to control the output power. In the inverting circuit, the IGBT and frequency tracing circuit is applied to achieve high speed and accurate soft switching control. The adoption of new technologies not only improves the quality and reliability of the machine, but also solve the technology problem on large power induction heating machine and makes it possible to work 100% duty cycle.

Based on the second generation technology , soft switching of the IGBT is improved both in the voltage regulate circuit and the inverting circuit to ensure machines working smoothly at high frequency and high power. Because the oscillating capacitor is connected with the primary coil of the high frequency transformer, by using large power oscillating capacitor, HF-70AB induction heater is characterized with low price, and without high voltage and low consumption on high frequency transformer.

Advantages of timer function

- Heating power, retaining power, heating time, retaining time and cooling time can be preset and adjusted, this makes it possible to control the heating curve and heating time.

- It is suitable to use in the repeated heating or high speed heating of small parts.

- When using in brazing, with proper timing parameters, rapid heating and retaining can be achieved to keep the temperature while the brazing material is melted and then to let the brazing material spread smoothly to form good joint.

Advantages of separated transformer

- In induction heating machines, the high frequency transformer is separated from the generator, with 2 meters connecting cable at least.

- It is suitable to use in the dirty or corrosive surroundings, the generator can be put in a clean space to increase the reliability.

- With the small size and light weight of the separated transformer, it is convenient to use in the production line and easily assembled inside the machinery or moved mechanism.