-

Application

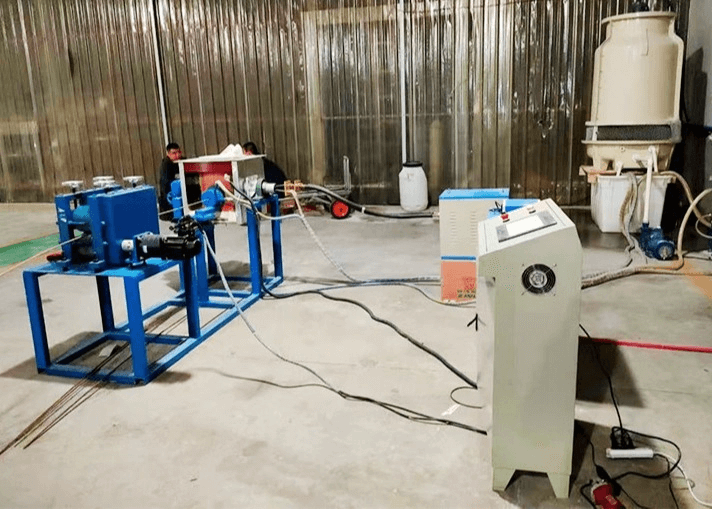

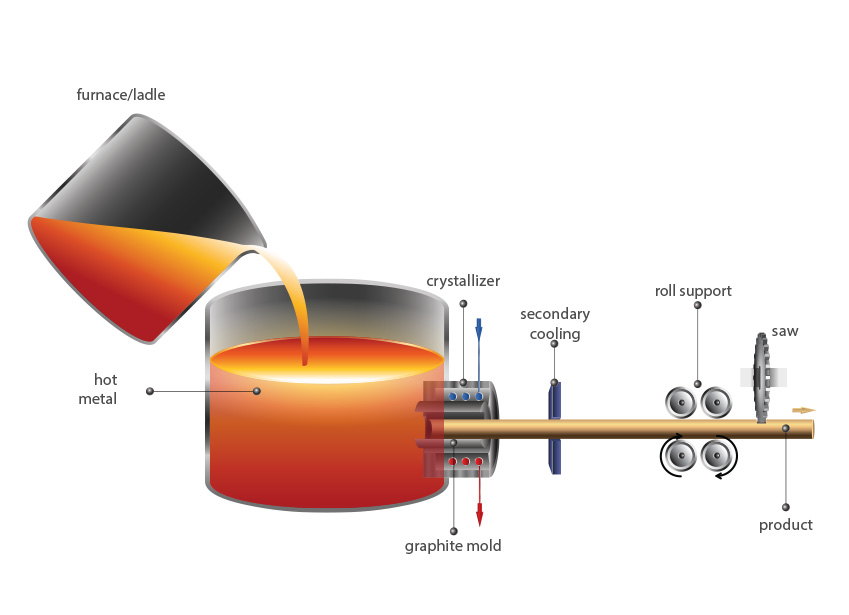

Horizontal Continuous Casting Machine is a production lines for producing the rod/bar、 tube/pipe、plate、billet、wire、strip of copper/brass/bronze. And This production lines are widely service for the industries like produce the electric wire, cable, electron, lock making, water heating equipments, refrigeration .

-

Specifications

Output

Below 200kg/h

Furnace body

Integrated melting & Holding furnace, customized

Melting/casting metal

copper, brass, bronze.

Type

Horizontal machine

Power supply

Transistor (IGBT)

Power

Customized

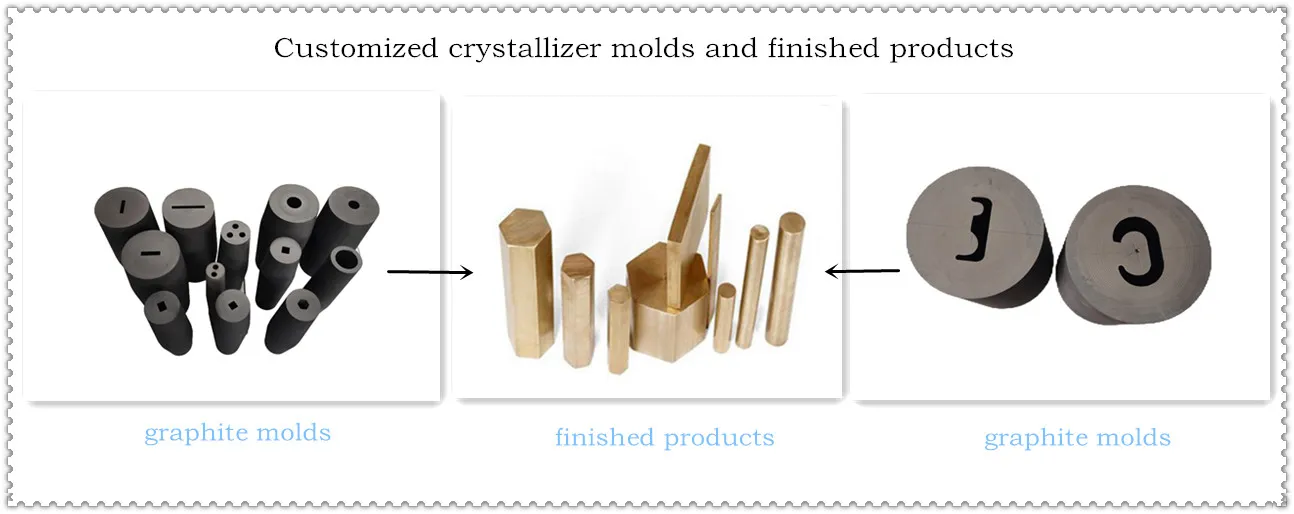

Crystallizer

water cooling sleeve + graphite mold

Stands

Customized

Traction mode

servo motor

Control system

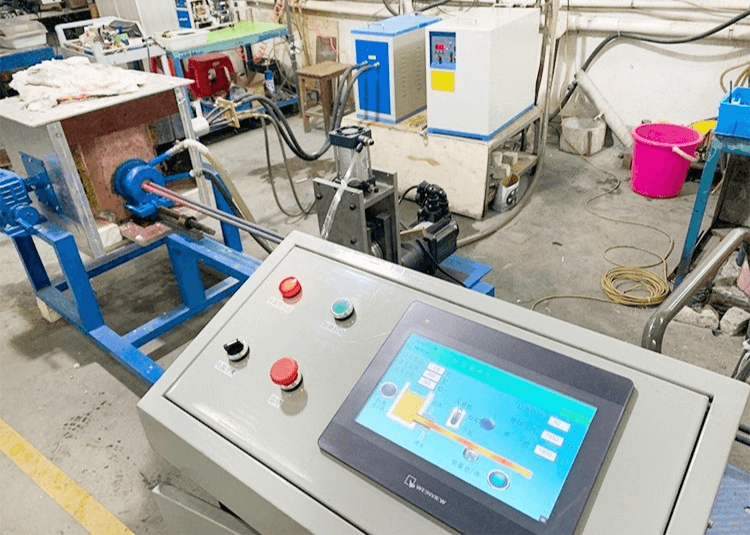

PLC control

Traction speed

0.1-0.5m/min

Available size

Φ8-60mm

Main Composed Parts of small horizontal continuous casting machine:

1. Medium frequency induction heating power supply.

2. Furnace body. Melting furnace and holding furnace are integrated, The holding furnace can be used separately, also can be used with melting furnace together.

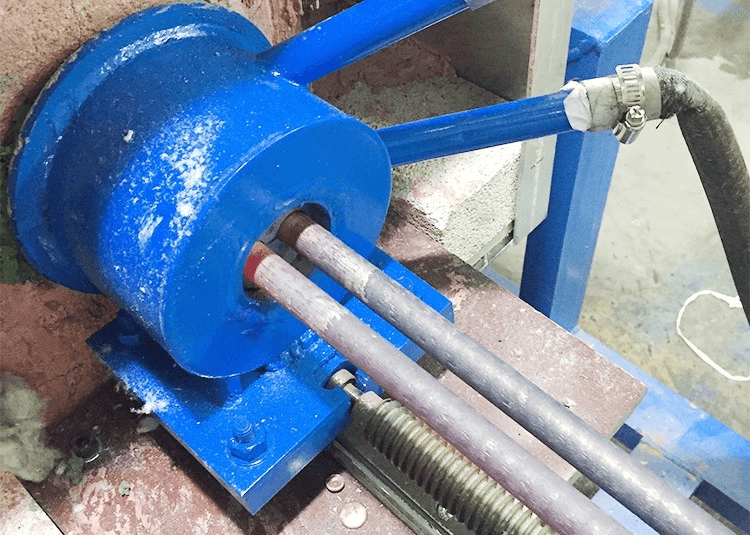

3. Crystallizer.

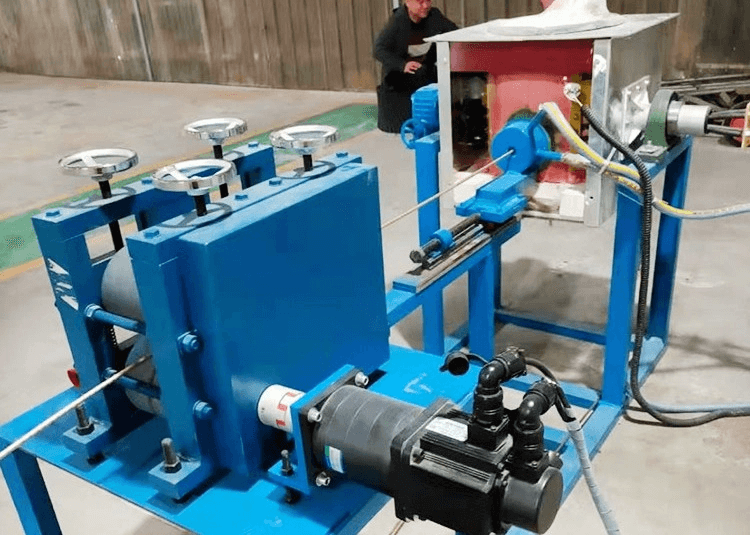

3. Traction machine.

4. Temperature controller.

5. Water cooling system.

6. Electric control system.

7. Coiling machine.

8. Accessories.

-

Features

1.The medium frequency induction heating power supply adopts the most advanced transistors and original imported electric devices and drive inverter technology, 1-20KHZ automatic tracking frequency, one-key start, fast heating, energy saving, electromagnetic stirring, uniform temperature and other characteristics.

2.Best quality silicon carbide isostatic graphite crucible furnace, which has a long life and slow oxidation and rapid heating. The furnace body adopts fixed traction and fast dumping.

3.High temperature resistant platinum rhodium thermocouple temperature measurement connection intelligent temperature control meter temperature measurement accuracy ± 5 ℃, automatic temperature control and power on/off function, to ensure the furnace and discharge port temperature balance, The fluidity of the solution makes the product dense after the crystallization is drawn, and the surface is smooth and traceless.

4.The non-ferrous metal crystallization mold adopts high-purity graphite, the inner surface is coated to ensure smoothness, oxidation resistance and size, and the external water flow is uniform and the water-cooled water jacket.

5.The traction machine adopts high-precision intelligent motor drive combination, which can adjust forward and backward, traction beat, traction speed can be accurate to 0.01MM, and pause and tow time can be accurate to 0.01 second.

6.The crystallization mold replacement is fast and convenient, and can be completed within 5 minutes. The mold and crucible fit closely to avoid metal leakage.

-

-

Customer comments

Induction Heaters CatalogHigh Frequency SeriesSuperaudio Frequency SeriesUltrahigh Frequency SeriesMedium Frequency MF SeriesMedium Frequency MFS Series DSP All Digital Induction Heating MachinesInduction Melting FurnaceHorizontal Continuous Casting MachineInduction Forging FurnaceInduction Hardening MachineInduction Brazing MachineMotorcycle Wheel Hub Brake Ring Heating MachineELectric Motor Induction HeatersMobile Handheld Induction HeatersAir cooled induction heaterWater Cooling system

Small horizontal continuous casting machine for Copper brass bronze rod/bar/Plate/Pipe/tube/strip/wire

Small horizontal continuous casting machine for Copper brass bronze rod/bar/Plate/Pipe/tube/strip/wire