-

Specifications

Vacuum tube high frequency induction brazing machine for cookware bottom brazing.

Model

V-60kw

V-100kw

V-150kw

Power supply type

Vacuum tube

Vacuum tube

Vacuum tube

Input voltage

3phases 380V 50-60HZ

3phases 380V 50-60HZ

3phases 380V 50-60HZ

Output power

60KW

100KW

150KW

Frequency

200-300KHz

200-300KHz

200-300KHz

Cookware size

Φ80-320mm, H ≤350mm

Φ80-390mm, H ≤350mm

Φ80-590mm, H≤600mm

Aluminum disc size

Φ80-310mm, thickness 0.4mm-12mm

Φ80-380mm, thickness 0.4mm-12mm

Φ80-580mm, thickness 1.5mm-12mm

Induction head

Φ320mm x 2pcs

Φ430mm x 2pcs

Φ320mm x 2pcs,

Φ630mm x 2pcs

Control panel

Trouble shooting & complete self protected

Worm gear motor

with braking system

Inductor & cooling plate

inductor Φ320mm, cooling plate320x320mm

inductor Φ430mm, cooling plate430x430mm

inductor Φ630mm, cooling plate630x630mm

cooling system (air cooled /water cooled/oil cooled)

water cooled

Max. brazing temperature

900℃

Max. workshop temperature

40℃

Overall size

2450 x 3100 x 2000mm

2650 x 3100 x 2000mm

2850 x 3100 x 2000mm

Net weight

about 4100kg

4200kg

4400kg

Gross weight

about 4300kg

4400kg

4600kg

-

Description

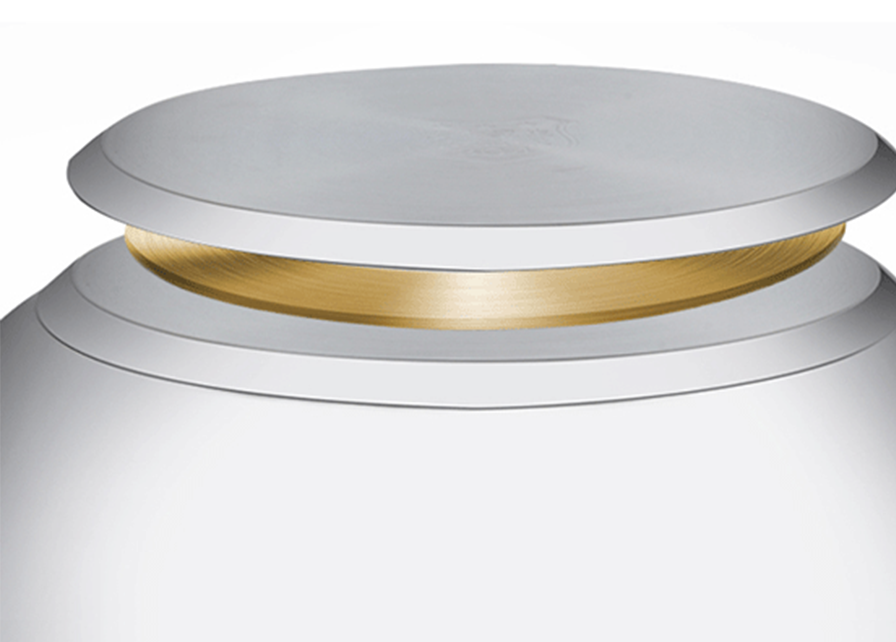

Cookware pan pot bottom induction brazing machine is mainly used for cookware compound bottom welding of stainless steel pan, aluminum pot, pot, kettle,and also can be used for plane heating of other workpiece. Cookware Pan and pot bottom brazing machine is an mechanical, hydraulic and electrical integrated equipment controlled by several sets microcomputer. The main performance index takes the leading position at home and aboard.

According to the difference of heating power supply and welding diameters, this cookware sandwich bottom induction brazing equipment can be divided into a variety of models, such as:

A. Transistor high frequency brazing machine

Features:

Using high power transistor, safety and reliability, energy saving.

Uniform heating and good welding quality.

Fast heating speed and high production rate.

Digital display of operating mode, simple operation and easy maintenance.

Power: 50KW, 80KW, 100KW, 150KW

Frequency: 200-300KHz

Welding diameter: 100-500mm

B. Vacuum tube high frequency brazing machine

Features:

Using traditional vacuum tube, the technology is mature and reliable.

Fast heating speed and high production efficiency.

The overall design is reasonable, small heat loss, and beautiful appearance.

Internal pressurizer, low price and small investment.

Digital display of operating mode and easy maintenance

Power: 60KW, 100KW, 150KW

Frequency: 200-300KHz

Welding diameter: 100-500mm

-

Video

-

Main Characteristics

1. Using traditional vacuum tube, the technology is mature and reliable.

2. Fast heating speed and high production efficiency.

3. The overall design is reasonable, small heat loss, and beautiful appearance.

4. Internal pressurizer, low price and small investment.

5. Digital display of operating mode and easy maintenance

6. Electron tube mode, high voltage resistance ability:

1) Heat evenly and stably.

2) Not easy to spark, high resistance ability for high voltage ignition during brazing.

7. Copper tube cooling:

Capacitors are protected by water cooling from copper tube, better safety and cooling performance.

8. Separate water cooling for internal part and external part:

To protect the important components from impurities and keep longer life, important components of machine internal part are cooled by distilled water, we call that internal recycling. Distilled water and other machine parts are cooled by normal water, it called external recycling.

9. Safety protection:

1)There are sensors on the cabinet door of oscillating section and inner electric cabinet. Power of the whole machine will be cut off and machine will stop running if machine door is opened during machine working. It can protect the worker from getting injured because of the wrong operation. Also prevent the machine from being damaged because of special situation.

2)Inner water cooling performance will be affected if water pressure is not enough and water level of outer connection is too low. Water temperature become too high, then high voltage can not work. There is indicator light on the machine panel will flash and remind the operators.

10. Components brand:

Machine components are of reliable quality and superior performance to extend the machine life, ensure the stable working and improve finished product quality. They are brand from USA, and and China best domestic product.

11. Working table adaptation:

It can be used for the brazing for both small size and big size product according to production requirement.

-

Application

Cookware pan pot bottom induction brazing machine is mainly used for cookware compound bottom brazing of stainless steel, copper or aluminum pan, pot, kettle, and also can be used for plane heating of other workpiece. Cookware Pan and pot bottom brazing machine is an mechanical, hydraulic and electrical integrated equipment controlled by several sets microcomputer.

multilayer compound bottom brazing of die casting aluminum pan pot, copper pot, aluminum pot, stainless steel pot and other cooking utensil. for example, fry pan, cooking pot, stockpot, milk pot, Casserole, pressure cooker, Rice cooker, steamer pot, Coffee Pots, Saucepans, Dutch oven and other induction cooker cookware utensils.

-

Customer comments

Induction Heaters CatalogHigh Frequency SeriesSuperaudio Frequency SeriesUltrahigh Frequency SeriesMedium Frequency MF SeriesMedium Frequency MFS Series DSP All Digital Induction Heating MachinesInduction Melting FurnaceHorizontal Continuous Casting MachineInduction Forging FurnaceInduction Hardening MachineInduction Brazing MachineMotorcycle Wheel Hub Brake Ring Heating MachineELectric Motor Induction HeatersMobile Handheld Induction HeatersAir cooled induction heaterWater Cooling system

Vacuum tube cookware bottom induction brazing machine

Cookware Bottom Brazing Machine

1. Using traditional vacuum tube, the technology is mature and reliable.

2. Fast heating speed and high production efficiency.

3. The overall design is reasonable, small heat loss, and beautiful appearance.

4. Internal pressurizer, low price and small investment.

5. Digital display of operating mode and easy maintenance

6. Electron tube mode, high voltage resistance ability: