-

Main Applications

Induction forging furnace is used for heating of bars and rods larger than Φ12mm or square or other shape stuff in the shaping of screws, nuts, valves, locks and other metal parts, the material can be steel ,stainless steel, copper, brass, bronze, aluminum and so on, the heating can be the whole heating and partial heating , such as end heating or middle part heating.

-

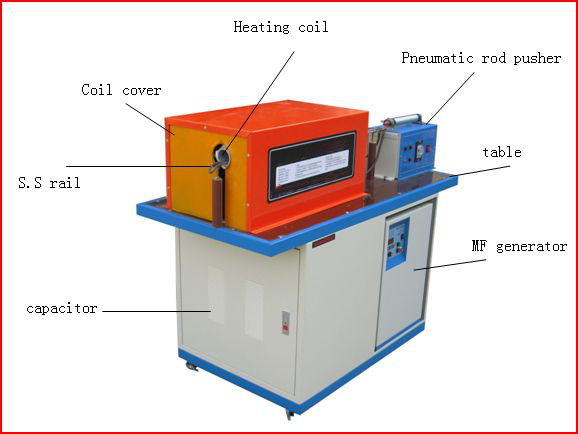

The composing of the induction forging furnace

1.Induction heating power supply

2. Induction heating coil and guide rail and coil cover.

3. pneumatic rod feeder.

4. control system.

5. water cooling system.

For some application, the infrared temperature sensor, temperature controller and automatic rod feeding systems can also be included if ordered.

-

Main models and heating ability

Models Power Recommend application Heating capacity for Steel or stainless steel to 1200℃,KG/Hour Heating capacity for copper to 700℃,KG/Hour MF-35 induction forging furnace 35KW Φ15-30 rod heating 1.25KG/min 1.75KG/min MF-45 induction forging furnace 45KW 1.67KG/min 2.33KG/min MF-70 induction forging furnace 70KW Φ15-50 rod heating 2.5KG/min 3.5KG/min MF-90 induction forging furnace 90KW Φ25-50 rod heating 3.33KG/min/td> 4.67KG/mintd> MF-110 induction forging furnace 110KW 4.17KG/min 5.83KG/min MF-160 induction forging furnace 160KW Φ50 up rod heating 5.83KG/min 8.26KG/min -

Main features of the MF induction forging furnace:

1.Wide frequency range from 1KHZ to 20KHZ, frequency can be designed to satisfy different size of the heated workpiece. And the actual frequency is depended on the coil and the compensating capacitor designed. When heating small rods, frequency can be designed higher to achieve high heating efficiency, but to heat the thick rods, lower frequency is needed to maintain heat penetrating.

2.The heating coil can be 500mm to 1 meter and up, several pieces are heated at the same time to make sure the penetrating effect. Coil size is depended on the rod size, and coils can be easily changed.

3.In the continuous heating process, the load inside the coil is stable, thus to overcome the great heating power change caused by the great change of the load during the heating course from cool to 1100℃, the actual power can reach more than 85% of the rated power of the machine.

4.Pneumatic rod feeding system is applied, only the heating power and the feeding speed are adjusted to send the rod out continuously by step. It is very convenient to operate.

5.Even when heating non-ferrous metals like copper or aluminum, the actual power can also reach more than 85% of the rated power of the machine by design the coil properly and match the compensating capacitor correctly. 3.1KG copper or brass can be heated to 700℃ per kilowatt in an hour.

6.compared with SCR medium frequency generator, our MF induction forging furnace is more efficient and consumes about 15-20% less power. and it is small size, easy maintenance.

-

Customer comments

Induction Heaters CatalogHigh Frequency SeriesSuperaudio Frequency SeriesUltrahigh Frequency SeriesMedium Frequency MF SeriesMedium Frequency MFS Series DSP All Digital Induction Heating MachinesInduction Melting FurnaceHorizontal Continuous Casting MachineInduction Forging FurnaceInduction Hardening MachineInduction Brazing MachineMotorcycle Wheel Hub Brake Ring Heating MachineELectric Motor Induction HeatersMobile Handheld Induction HeatersAir cooled induction heaterWater Cooling system