-

Technical Parameter

Model

SK-2000

SK-2500

SK-3000

SK-4000

Max heating length(mm)

2000

2500

3000

4000

Max heating diameter(mm)

500

500

500

500

Max holding length(mm)

2000

2500

3000

4000

Max weight of workpiece(Kg)

150

150

150

150

workpiece rotation speed(r/min)

0-300

0-300

0-300

0-300

workpiece moving speed(mm/min)

0-2500

0-2500

0-2500

0-2500

Cooling method

Hydrojet cooling

Hydrojet cooling

Hydrojet cooling

Hydrojet cooling

Input voltage

3P 380V 50Hz

3P 380V 50Hz

3P 380V 50Hz

3P 380V 50Hz

Motor power

4.5KW

4.5KW

4.5KW

4.5KW

Dimension LxWxH (mm)

1900 x900 x2400 1900 x900 x2900

1900 x900 x3400

1900 x900 x4300

weight(Kg)

1200

1300

1400

1500

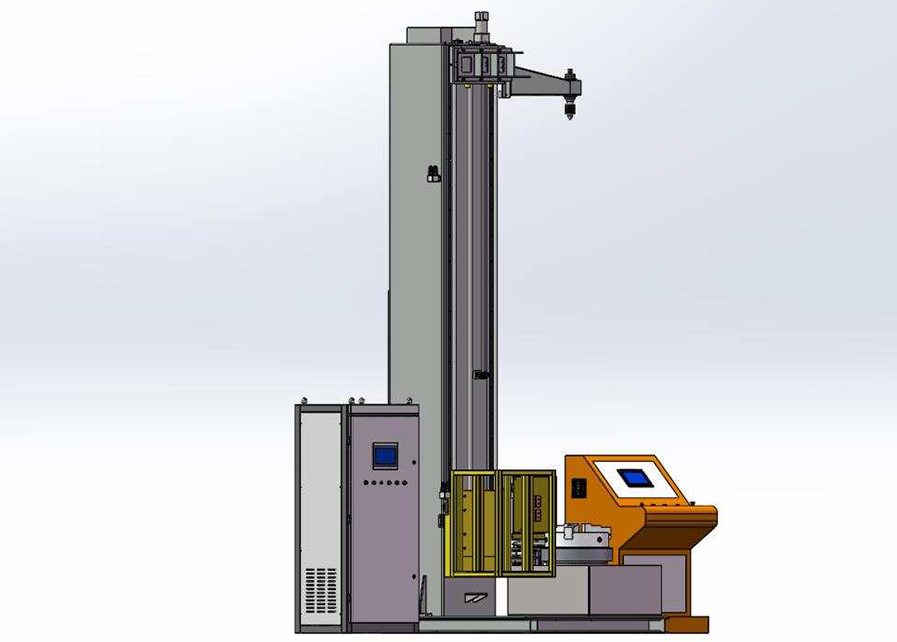

This series hardening machine tool uses numberic control technology, has continuous, simultaneous, sectionally-continuous and sectionally-silultaneous quenching functions, it is mainly used for induction quenching of shafts, discs, pins and gears, and featured by high quenching precision. hardening machine tool used by connecting with medium frequency, superaudio frequency, high frequency and ultrahigh frequency induction heating machine.

CNC hardening machine tool feature:

1.CNC system:The high-frequency quenching machine CNC system can compile and store a variety of quenching process programs according to different workpiece requirements.

2.HMI: programming type and human machine interface displays in English and Chinese.

3.Control adjust: it can control the heating power to start, stop, parts heating and cooling time, rotation speed and movement speed.

4.Lathe: adopt welded structure with good rust-proof functions.

5.Top adjustment parts: adopt electric adjustment, to realize clamping of different length work piece.

6.Work table system: adopt ball screw and servo motor to drive, driving light, high guide precision and accurate positioning.

7.Main shaft rotation system: adopt variable frequency regulating to realize parts rotation speed continuous adjusted.

8.Electric control part: the machine tool has power-loosing protection function, has high safety and reliability.

9.Frame: made by thick steel plates, with window and sliding doors, prevent water splash, easy to load parts and monitor hardening process.

-

Customer comments

Induction Heaters CatalogHigh Frequency SeriesSuperaudio Frequency SeriesUltrahigh Frequency SeriesMedium Frequency MF SeriesMedium Frequency MFS Series DSP All Digital Induction Heating MachinesInduction Melting FurnaceHorizontal Continuous Casting MachineInduction Forging FurnaceInduction Hardening MachineInduction Brazing MachineMotorcycle Wheel Hub Brake Ring Heating MachineELectric Motor Induction HeatersMobile Handheld Induction HeatersAir cooled induction heaterWater Cooling system